This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Niobium

Used for high grade structural steel industry, lowers the consumption of steel, therefore reducing energy uses, while strengthning its composition. Strategic in the new economy

Where is it used?

Steel

Used for the high-grade structural steel industry, it lowers steel consumption, therefore reducing energy uses and strengthening its composition. Adding 0.03% to 0.05% niobium to steel can increase the yield strength of steel by more than 30%. Therefore, adding niobium to steel can not only improve strength, but also improve toughness, high temperature oxidation resistance and corrosion resistance.

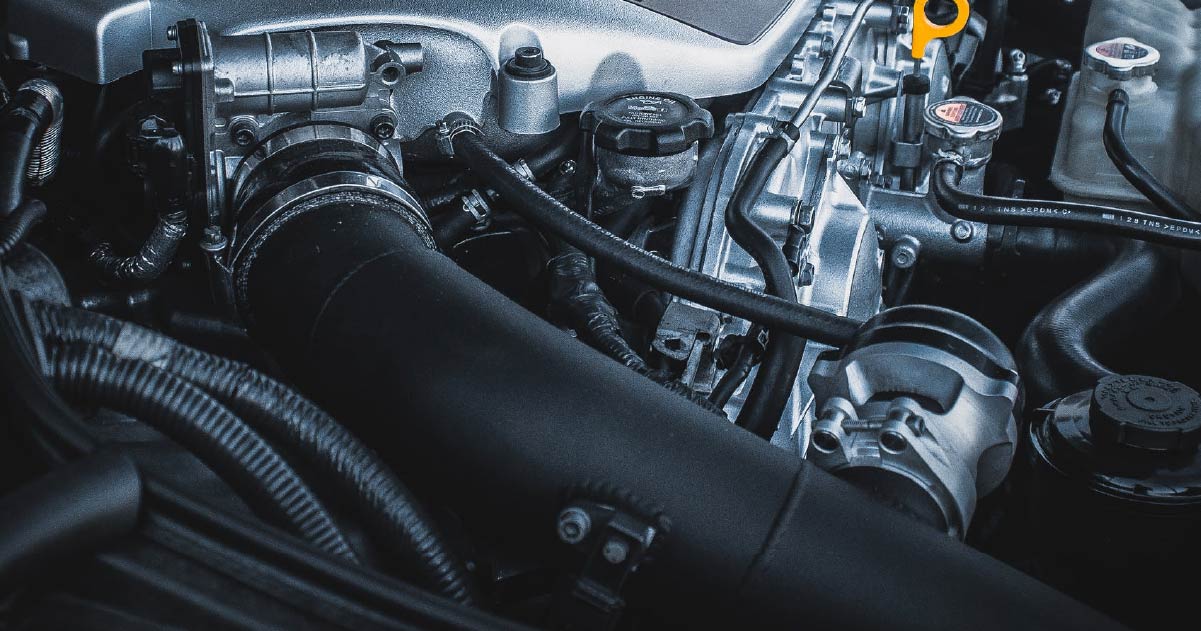

Automotive

Extensive use in the automotive industry as it reduces the use of steel, adding to high strength of parts.

Aerospace

Niobium alloy superconductors and electronic components are widely used in the aerospace industry. It also has extensive applications in gas turbines, rocket subassemblies, turbocharger systems, heat resisting and combustion equipment. Niobium precipitates a hardening phase within the grain structure of the superalloy.

Medicine

Extensively used in medicine, in prosthetics and implant devices such as pacemakers.

How is it obtained?

1

A grinding process is applied to reach the liberation size of the metal ores.

2

Gravimetric methods and water are used to achieve the separation by density to obtain the metallic mineral concentrate.

3

High intensity magnetic separation is applied.

4

It undergoes a chemical process to transform the metallic ore to mineral salts.

5

The concentrate obtained is subjected to a high temperature oxide reduction process to obtain niobium metal.